Blog

Home > Blog

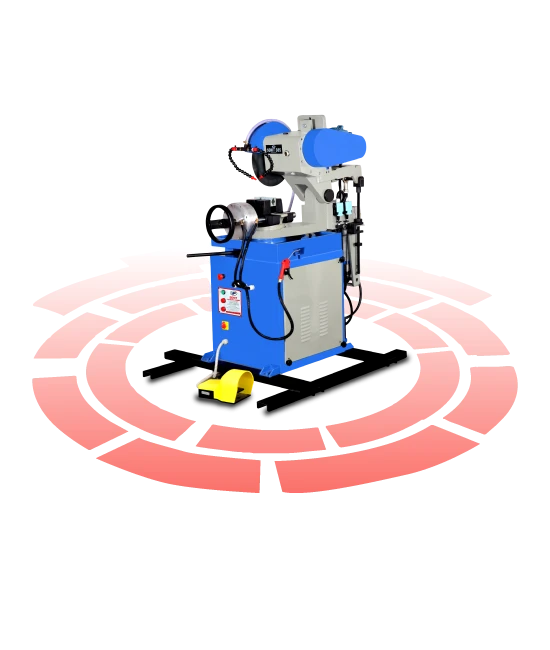

Circular saw high-speed metal cutting machines are engineered for precision, speed, and durability—making them essential for industries like fabrication, construction, and heavy engineering.

In this blog, “How Circular Saw High Speed Metal Cutting Machines Work? – Check Our Website Today!”, we simplify the working mechanism of these powerful machines to help you understand why they’re a game-changer in metal processing.

These machines use a high-RPM circular blade made from hardened steel or carbide-tipped material, which spins at incredible speeds to deliver clean, burr-free cuts through solid metal bars, pipes, and profiles.

The cutting process is driven by a robust motor and is often supported by a hydraulic or pneumatic clamping system that holds the material securely in place, ensuring both safety and cutting accuracy.

Advanced models include features like automatic feeding, length setting, and programmable control panels for consistent production output with minimal manual intervention.

Ideal for cutting stainless steel, mild steel, aluminum, and other alloys, these machines reduce heat-affected zones and improve blade life with built-in cooling systems.

Whether you're setting up a new production line or upgrading existing equipment, this guide explains how these high-speed machines can significantly boost efficiency, reduce material wastage, and improve finish quality.

Similar Post, You may interested!

Search

Latest Blog

Request A Quotation

Need help? Chat with us

Click below to connect with our representative

|

Sales Inquiry +919638565245 Start Chat |

|

Sales Inquiry +919974677623 Start Chat |