Blog

Home > Blog

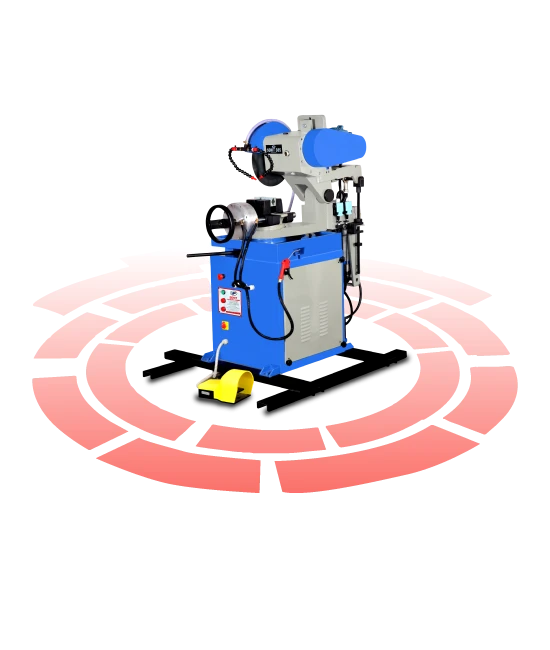

Semi automatic pipe cutting machines have become a preferred choice for industries seeking a perfect balance between manual control and automated precision.

In this blog, “Uses and Benefits of Semi Automatic Pipe Cutting Machines – Shop Now!”, we explore why these machines are widely used across fabrication units, construction sites, plumbing workshops, and manufacturing plants.

These machines are designed to handle a wide variety of materials like steel, aluminum, copper, and PVC, offering consistent and clean cuts with minimal manual intervention.

The semi automatic function allows operators to set pipe length and position manually, while the cutting process itself is executed with high accuracy using hydraulic or pneumatic systems.

This not only reduces labor fatigue but also boosts cutting speed and productivity.

Key benefits include lower operational costs, ease of maintenance, compact design, and adaptability to multiple pipe sizes and thicknesses.

Whether you’re starting a new workshop or expanding your production line, this blog will help you understand how investing in a semi automatic pipe cutting machine can improve efficiency, reduce errors, and deliver long-term value.

Ready to upgrade your process? Discover top models and shop now for the best deals!

Similar Post, You may interested!

Search

Latest Blog

Request A Quotation

Need help? Chat with us

Click below to connect with our representative

|

Sales Inquiry +919638565245 Start Chat |

|

Sales Inquiry +919974677623 Start Chat |