Blog

Home > Blog

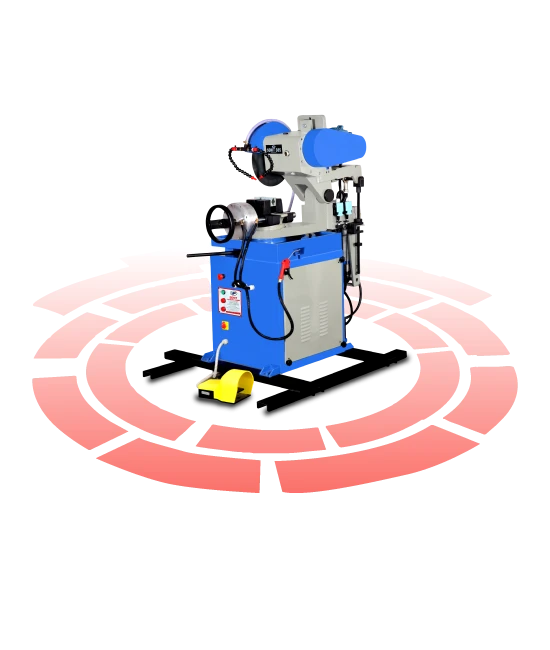

An Automatic Pipe Cutting Machine is a technologically advanced solution designed to cut pipes with speed, precision, and minimal human intervention.

In this blog, “What Is an Automatic Pipe Cutting Machine and Why Use It?”, we explore how these machines revolutionize pipe processing for industries like metal fabrication, construction, automotive, and manufacturing.

Equipped with programmable controls, servo motors, sensors, and sometimes CNC systems, automatic pipe cutters streamline the entire cutting process—eliminating manual setup and increasing productivity.

You’ll learn how these machines operate using automated feeding, clamping, measuring, and cutting mechanisms, ensuring each cut is accurate and consistent regardless of volume.

The blog also highlights why they’re ideal for high-volume or continuous production, offering benefits such as reduced material wastage, better edge quality, lower labor dependency, and faster turnaround times.

We’ll walk you through different types of automatic machines—cold saw, laser, plasma, and blade-based—along with their suitability for various pipe materials and sizes.

Whether you're a production head aiming to improve throughput or a business owner looking to reduce operational costs, this guide shows how an automatic pipe cutting machine can enhance your efficiency and output quality while saving time and money in the long run.

Similar Post, You may interested!

Search

Latest Blog

Request A Quotation

Need help? Chat with us

Click below to connect with our representative

|

Sales Inquiry +919638565245 Start Chat |

|

Sales Inquiry +919974677623 Start Chat |